Yongxiang - H13 Steel Specialists

In the realm of high-performance tooling, H13 tool steel stands as a cornerstone material, renowned for its exceptional strength, thermal resistance, and versatility. At the forefront of producing this premium alloy is Yongxiang, a leading H13 steel manufacturer based in China, dedicated to delivering excellence in high temperature tool steel solutions for industries worldwide.

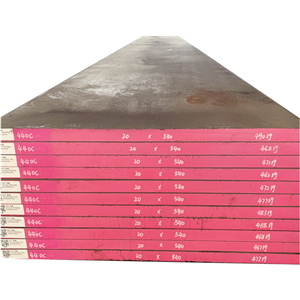

Yongxiang’s expertise lies in crafting H13 steel that meets the rigorous demands of modern manufacturing. H13, a hot work tool steel, is prized for its ability to withstand extreme temperatures without losing its structural integrity, making it ideal for applications such as die casting, extrusion, and forging. Yongxiang’s advanced metallurgical processes ensure that every batch of H13 steel produced adheres to stringent quality standards, offering superior toughness, hardness, and resistance to thermal fatigue.

What truly distinguishes Yongxiang is its role as a custom H13 steel supplier. Recognizing that no two industries or applications are identical, the brand specializes in tailoring H13 steel specifications to meet unique customer requirements. Whether it’s adjusting the alloy composition for enhanced wear resistance, optimizing heat treatment processes for specific performance criteria, or producing custom-sized billets or bars, Yongxiang’s engineering team collaborates closely with clients to deliver bespoke solutions. This custom approach has earned the brand a reputation for flexibility and reliability across sectors like automotive, aerospace, and tool and die manufacturing.

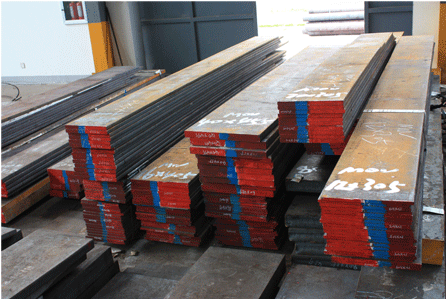

As a manufacturer rooted in China, Yongxiang leverages cutting-edge technology and a skilled workforce to maintain a competitive edge. The brand’s state-of-the-art facilities are equipped with advanced melting, forging, and heat treatment equipment, enabling precise control over every stage of production. This commitment to innovation ensures that Yongxiang’s H13 steel not only meets but often exceeds international standards, including AISI H13, DIN 1.2344, and JIS SKD61.

Quality assurance is non-negotiable at Yongxiang. The brand employs rigorous testing protocols, including ultrasonic inspection, hardness testing, and metallurgical analysis, to guarantee the consistency and reliability of its H13 steel. This dedication to excellence has made Yongxiang a trusted partner for global OEMs and tooling specialists seeking dependable, high-performance materials.

Sustainability is another cornerstone of Yongxiang’s operations. The brand is committed to minimizing its environmental footprint through energy-efficient manufacturing processes and responsible sourcing of raw materials. By prioritizing eco-friendly practices, Yongxiang ensures that its high temperature tool steel solutions contribute to a greener, more sustainable future.

For businesses seeking a custom H13 steel supplier that combines technical expertise with a customer-centric approach, Yongxiang is the ideal choice. The brand’s ability to deliver tailored solutions, backed by decades of experience and a relentless focus on quality, makes it a standout in China’s competitive steel manufacturing landscape.

In conclusion, Yongxiang is more than just an H13 tool steel manufacturer; it’s a catalyst for innovation in high-temperature applications. By pushing the boundaries of what’s possible with H13 steel, Yongxiang is empowering industries to achieve greater efficiency, durability, and success. For those in search of a partner that understands the nuances of custom tool steel solutions, Yongxiang stands ready to deliver excellence.