Yongxiang H21/SKD5: Precision Steel

In the high-stakes world of industrial tooling, the choice of material can make or break operational efficiency. H21 tool steel and its Japanese equivalent SKD5 (3Cr2W8V) have emerged as critical alloys for applications demanding extreme heat resistance, toughness, and dimensional stability. Yongxiang, a premier H21 tool steel manufacturer and custom SKD5 steel supplier based in China, is redefining industry standards by delivering tailored solutions that meet global demands for precision and durability.

H21 & SKD5: The Alloys for Extreme Environments

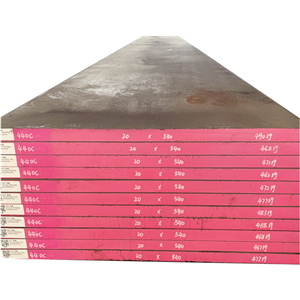

H21 tool steel, classified as a hot-work steel, is engineered to withstand prolonged exposure to high temperatures without losing hardness or cracking. Its composition—typically 0.35% carbon, 2.2–2.7% chromium, and 0.5–1.2% vanadium—ensures a balance of wear resistance and thermal fatigue strength. This makes it ideal for manufacturing dies, extrusion tools, and forging components in industries like automotive and aerospace.

SKD5 (3Cr2W8V), the Japanese counterpart to H21, shares similar properties but is optimized for specific applications requiring enhanced toughness under cyclic thermal loads. Both alloys excel in scenarios where conventional steels would deform or fail, such as die-casting aluminum or processing abrasive materials.

Yongxiang: China’s Leader in Custom Tool Steel Solutions

As a custom SKD5 steel supplier and H21 tool steel manufacturer, Yongxiang combines cutting-edge technology with decades of metallurgical expertise. Headquartered in China—a global powerhouse in steel production—the company operates state-of-the-art facilities equipped with advanced vacuum melting, electroslag remelting (ESR), and precision forging capabilities.

Key advantages of partnering with Yongxiang include:

Tailored Manufacturing: From small-batch prototypes to large-scale orders, Yongxiang accommodates custom specifications for chemical composition, heat treatment, and surface finishes.

Quality Assurance: Rigorous testing, including ultrasonic flaw detection and metallographic analysis, ensures compliance with AISI, JIS, and GB standards.

Cost Efficiency: Leveraging China’s competitive manufacturing ecosystem, Yongxiang offers premium-grade H21 and SKD5 steels at accessible price points.

Global Logistics: The company’s streamlined supply chain ensures timely delivery to clients worldwide, backed by technical support throughout the product lifecycle.

Applications Across Industries

Yongxiang’s H21 and SKD5 steels serve diverse sectors:

Automotive: High-performance dies for engine blocks and transmission components.

Aerospace: Turbine blade molds and structural part extrusion tools.

Electronics: Precision stamping tools for miniaturized components.

Energy: Tooling for oil and gas drilling equipment.

Innovation Driven by Customization

Yongxiang’s R&D team continuously refines its processes to enhance alloy performance. For instance, the company’s proprietary cryogenic treatment reduces residual stresses in H21 steel, extending tool life by up to 30%. Similarly, SKD5 grades are optimized with micro-alloying additions to improve crack resistance in die-casting applications.

Sustainability and Ethical Manufacturing

In alignment with global ESG trends, Yongxiang prioritizes eco-friendly practices, including energy-efficient electric arc furnaces and closed-loop water recycling systems. The company also adheres to strict labor standards, ensuring ethical sourcing and workplace safety.

Why Choose Yongxiang?

For businesses seeking a custom SKD5 steel supplier or H21 tool steel manufacturer that delivers reliability, innovation, and cost-effectiveness, Yongxiang stands out as China’s trusted partner.