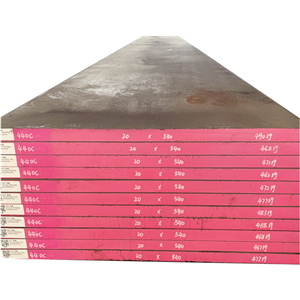

Yongxiang is P20 1.2085 Steel: Mould Mastery

In the intricate world of plastic injection moulding, where precision and resilience define success, P20 DIN 1.2085 Steel Plate stands as a cornerstone material for crafting tools that endure the rigors of high-volume production. Renowned for its balanced mechanical properties and corrosion resistance, this pre-hardened plastic mould steel is a favorite among custom plastic mould steel manufacturers seeking reliability without compromise. Enter Yongxiang, a brand that epitomizes China’s prowess in steel manufacturing, offering tailored solutions that redefine excellence in mould plate production.

China’s Manufacturing Edge: Yongxiang Delivers Precision

China has cemented its reputation as a global manufacturing hub, and Yongxiang exemplifies this legacy in the steel sector. As a leading P20 steel plate supplier, Yongxiang combines decades of metallurgical expertise with cutting-edge technology to produce steel plates that meet and exceed industry benchmarks. What distinguishes Yongxiang is its unwavering commitment to custom solutions. Unlike mass producers, Yongxiang’s manufacturers engage deeply with clients to engineer P20 1.2085 steel plates tailored to exact specifications—whether it’s optimizing thickness for complex mould geometries or enhancing surface hardness for prolonged tool life. This bespoke approach ensures that every plate meets the unique demands of modern plastic moulding.

P20 DIN 1.2085 Steel Plate: The Foundation of Quality Moulds

P20 DIN 1.2085, a chromium-molybdenum alloy steel, is celebrated for its versatility in plastic mould applications. With a hardness range of 28-34 HRC, it offers an ideal blend of machinability and toughness, reducing lead times and production costs. For manufacturers in the plastic moulding industry, P20’s uniform hardness minimizes deformation during machining and polishing, while its inherent corrosion resistance (due to chromium content) prolongs mould lifespan in humid or chemically aggressive environments. Yongxiang’s P20 1.2085 steel plates elevate these benefits further, featuring consistent grain structure and purity levels that enhance dimensional stability and part quality. Whether used for automotive interiors, medical devices, or consumer electronics, Yongxiang’s plates ensure flawless replication and durability.

Customization: Yongxiang’s Key to Client Success

At Yongxiang, customization is more than a service—it’s a strategic partnership. As custom plastic mould steel manufacturers, the brand understands that every project has distinct challenges. Yongxiang’s engineers collaborate closely with clients to tailor P20 1.2085 steel plates, such as:

Thickness adjustments for deep-draw or high-cavity moulds.

Surface treatments (e.g., nitriding) for enhanced wear resistance.

Dimensional precision to meet tight tolerances in multi-cavity tools.

This level of custom service positions Yongxiang as a trusted ally for businesses aiming to differentiate their products in competitive markets.

Why Choose Yongxiang as Your Supplier?

As a premier P20 steel plate supplier, Yongxiang offers more than just material—it delivers value. Clients benefit from:

Rigorous quality inspections at every production stage.

Flexible order volumes to suit prototyping and mass production.

Technical expertise to optimize mould design and steel selection.

For manufacturers in China, Yongxiang’s partnerships drive innovation, pushing boundaries in sustainable practices (e.g., recycled steel alloys) and Industry 4.0 integration (e.g., real-time production tracking).

The Future of Mould Steel: Forged by Yongxiang

In an era where efficiency and sustainability are paramount, Yongxiang’s P20 DIN 1.2085 steel plates provide a competitive edge. By harnessing China’s manufacturing strengths and its own custom capabilities, Yongxiang empowers businesses to create moulds that meet the highest standards of precision and longevity. Whether you’re a boutique mould shop or a global OEM, partnering with Yongxiang means investing in a future where every plastic part is a testament to engineering excellence and environmental stewardship.