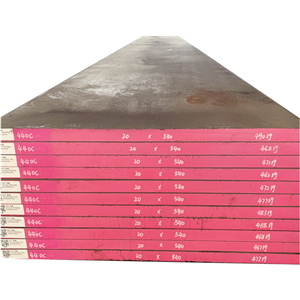

Yongxiang Steels: Precision in High Heat

In the realm of high-temperature tooling, where durability and performance under extreme conditions are non-negotiable, Yongxiang stands as a beacon of excellence. As a premier high temperature tool steel manufacturer based in China, Yongxiang specializes in crafting H13 tool steel and SKD61 mold steel—grades renowned for their unmatched toughness, thermal fatigue resistance, and machinability. For wholesalers and industrial partners seeking reliable, custom alloy steel solutions, Yongxiang’s expertise redefines the standards of quality and innovation.

Why H13 and SKD61? The Backbone of Resilience

H13 tool steel and SKD61 (its Japanese equivalent) are the workhorses of industries like die-casting, extrusion, and plastic injection molding. These steels excel in applications where temperatures soar above 500°C, retaining hardness and dimensional stability. Yongxiang’s proprietary refining processes enhance these inherent properties, ensuring its H13 and SKD61 steels outperform competitors in critical areas like red hardness, wear resistance, and crack resistance. For wholesale alloy steel suppliers, this translates to fewer production downtimes and longer tool lifespans for end-users.

Custom Solutions for Diverse Demands

Yongxiang understands that one size does not fit all in industrial manufacturing. The company’s strength lies in its ability to deliver custom steel solutions tailored to specific applications. Whether a client requires H13 tool steel with adjusted carbon content for enhanced toughness or SKD61 mold steel with optimized vanadium levels for improved thermal conductivity, Yongxiang’s engineers collaborate closely to refine alloy compositions. This level of customization ensures that every batch of steel meets—or exceeds—the unique demands of industries ranging from automotive to aerospace.

Precision Engineering from China’s Heartland

Headquartered in China, Yongxiang leverages advanced metallurgical expertise and cutting-edge technology. Its facilities feature vacuum degassing units, electroslag remelting (ESR) furnaces, and precision spectrometers, enabling rigorous control over steel purity and microstructure. This commitment to quality has earned Yongxiang certifications like ISO 9001 and NADCAP, assuring global partners of consistency and compliance. For high temperature tool steel manufacturers, such investments in infrastructure and expertise are the cornerstones of trust and reliability.

Sustainability and Efficiency in Every Batch

In an era where environmental stewardship is paramount, Yongxiang integrates sustainability into its operations. The company optimizes melting and refining processes to minimize energy consumption and waste, while recycling scrap steel to reduce raw material demand. Additionally, Yongxiang’s H13 and SKD61 steels are engineered for longer tool life, reducing the frequency of replacements and associated carbon footprints. For wholesale alloy steel suppliers, this eco-conscious approach aligns with the growing demand for greener industrial solutions.

Global Reach, Local Partnerships

Yongxiang’s clientele spans continents, from North American die-casters to European mold makers. The company’s deep understanding of international standards—such as AISI, JIS, and DIN—ensures seamless compatibility with global manufacturing workflows. For high temperature tool steel manufacturers, this global perspective is invaluable, as it allows Yongxiang to anticipate market trends and adapt rapidly to regional preferences. Whether a client needs a prototype batch or bulk orders, Yongxiang’s scalable processes deliver on time and within specification.

Collaborative Innovation for Tomorrow’s Challenges

Yongxiang views its role as more than just a supplier—it’s a partner in progress. The company’s R&D team actively engages with clients to co-develop next-generation steel alloys, pushing the boundaries of what’s possible in high-temperature applications. For wholesale alloy steel suppliers, such collaborations foster innovation and differentiation in competitive markets.

In the high-stakes world of high-temperature tooling, Yongxiang’s H13 tool steel and SKD61 mold steel are synonymous with excellence. As a trusted high temperature tool steel manufacturer in China, Yongxiang empowers wholesalers and industrial partners with custom, sustainable solutions that drive efficiency and profitability. With a focus on precision, innovation, and client-centric service, Yongxiang is not just meeting industry demands—it’s shaping the future of alloy steel manufacturing.